Quick Takeaways

- SiC Power Semiconductor Modules for EV Inverters Get Boost.

- The initiative focuses on developing next-generation silicon carbide solutions that simplify inverter integration while preserving technical performance and reliability.

SiC Power Semiconductor Modules for EV Inverters Get Boost

On the announcement date, SiC power semiconductor modules for EV inverters gained momentum as Fuji Electric Co., Ltd. and Robert Bosch GmbH revealed a strategic collaboration aimed at improving compatibility and flexibility in electric vehicle power electronics. The initiative focuses on developing next-generation silicon carbide solutions that simplify inverter integration while preserving technical performance and reliability.

Standardized SiC Power Semiconductor Modules for EV Inverters

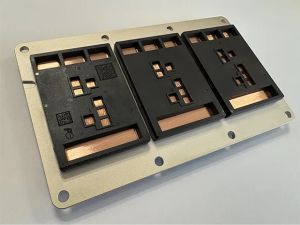

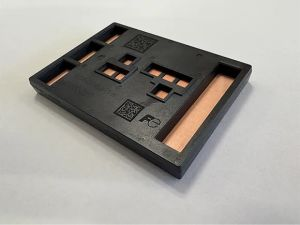

The partnership centers on creating SiC power semiconductor modules for EV inverters with standardized mechanical designs. By aligning outer package dimensions and terminal positioning, the two companies are enabling seamless interchangeability between modules, allowing inverter systems to adopt either supplier’s solution without physical redesign or revalidation.

The jointly developed modules are designed to be mechanically compatible, ensuring that inverter manufacturers can integrate them without modifying housing structures or mounting layouts. This standardization significantly reduces development complexity and engineering workload, especially for OEMs managing multiple vehicle platforms and production volumes.

Key technical advantages include:

Reducing Design Time and Procurement Risk

With compatible module architectures, EV manufacturers can shorten inverter development cycles while improving supply chain resilience. The ability to source modules from multiple suppliers reduces dependency risks and supports production continuity during demand fluctuations or component shortages.

This approach also enables:

Joint Development of Application Technologies

Beyond hardware compatibility, the collaboration extends to application-level engineering. The companies are working together on technologies related to thermal management, including advanced cooler design concepts, as well as optimized terminal connection methods suited for high-efficiency SiC operation.

Technical support will be provided to customers to ensure smooth adoption, covering:

By combining expertise in power semiconductors and automotive systems, the collaboration supports the broader shift toward more efficient, scalable, and resilient EV powertrain architectures, strengthening the role of silicon carbide technologies in next-generation electric mobility.

On the announcement date, SiC power semiconductor modules for EV inverters gained momentum as Fuji Electric Co., Ltd. and Robert Bosch GmbH revealed a strategic collaboration aimed at improving compatibility and flexibility in electric vehicle power electronics. The initiative focuses on developing next-generation silicon carbide solutions that simplify inverter integration while preserving technical performance and reliability.

Standardized SiC Power Semiconductor Modules for EV Inverters

The partnership centers on creating SiC power semiconductor modules for EV inverters with standardized mechanical designs. By aligning outer package dimensions and terminal positioning, the two companies are enabling seamless interchangeability between modules, allowing inverter systems to adopt either supplier’s solution without physical redesign or revalidation.

The jointly developed modules are designed to be mechanically compatible, ensuring that inverter manufacturers can integrate them without modifying housing structures or mounting layouts. This standardization significantly reduces development complexity and engineering workload, especially for OEMs managing multiple vehicle platforms and production volumes.

Key technical advantages include:

- Identical outer dimensions across compatible modules

- Matching terminal locations for electrical connections

- Simplified drop-in replacement within inverter assemblies

Reducing Design Time and Procurement Risk

With compatible module architectures, EV manufacturers can shorten inverter development cycles while improving supply chain resilience. The ability to source modules from multiple suppliers reduces dependency risks and supports production continuity during demand fluctuations or component shortages.

This approach also enables:

- Faster inverter validation and ramp-up

- Reduced redesign costs across model updates

- Greater flexibility in sourcing strategies

Joint Development of Application Technologies

Beyond hardware compatibility, the collaboration extends to application-level engineering. The companies are working together on technologies related to thermal management, including advanced cooler design concepts, as well as optimized terminal connection methods suited for high-efficiency SiC operation.

Technical support will be provided to customers to ensure smooth adoption, covering:

- Thermal optimization strategies

- Terminal and connection configurations

- System-level inverter integration guidance

By combining expertise in power semiconductors and automotive systems, the collaboration supports the broader shift toward more efficient, scalable, and resilient EV powertrain architectures, strengthening the role of silicon carbide technologies in next-generation electric mobility.

Company Press Release

Click above to visit the official source.

Share: