Quick Takeaways

- A new central drive dual-motor electric powertrain targets extreme-duty commercial vehicle applications.

- The system combines high torque, high efficiency, and redundancy-focused engineering for long-term reliability.

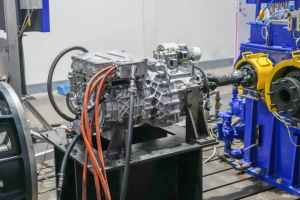

Zhejiang Wanliyang Co., Ltd. announced the successful prototype development and bench validation of its first central drive dual-motor powertrain, the CD400-4E320. The system marks a key step in advancing high-performance electric drivetrains engineered for demanding commercial vehicle operations.

The CD400-4E320 is now moving into vehicle integration and low-temperature validation phases. It is specifically developed for complex duty cycles such as long-distance freight corridors, mining operations, port logistics, and intensive urban construction environments, where durability, torque delivery, and energy efficiency are critical.

Central Drive Dual-Motor Powertrain for Heavy-Duty Applications

The central drive dual-motor powertrain adopts a coordinated dual-motor architecture tailored for heavy-load and high-resistance scenarios. By synchronizing motor output based on operating conditions, the system ensures stable power delivery across varied terrain and load profiles, improving drivability in extreme working environments.

Key target application scenarios include:

High-Efficiency Design and Performance Output

From a technical standpoint, the CD400-4E320 integrates a high-speed oil-cooled hairpin motor, a high-torque transmission system, and an integrated motor and transmission control unit. This compact configuration delivers more than 150 kilograms of weight reduction compared to equivalent single-motor solutions with similar output levels.

Performance highlights include:

Intelligent Control and Energy Optimization

An advanced intelligent control strategy enables real-time allocation of workload between the two motors. This dynamic distribution enhances overall energy efficiency while maintaining consistent torque output under varying operational demands. The control architecture also contributes to smoother power transitions and improved system responsiveness.

Reliability-Oriented Engineering for Long-Term Operation

To ensure operational robustness, the central drive dual-motor powertrain features a redundant drive configuration designed to maintain functionality under fault conditions. The fully helical gear transmission minimizes noise and vibration, while bidirectional oil pump lubrication and multi-stage filtration improve thermal management and component longevity.

During development, core subsystems such as heat dissipation, lubrication pathways, and control logic were systematically optimized to support sustained performance in high-load, long-duration use cases. Technical collaboration and cooperation agreements have already been established with multiple vehicle manufacturers to support future application deployment.

The CD400-4E320 is now moving into vehicle integration and low-temperature validation phases. It is specifically developed for complex duty cycles such as long-distance freight corridors, mining operations, port logistics, and intensive urban construction environments, where durability, torque delivery, and energy efficiency are critical.

Central Drive Dual-Motor Powertrain for Heavy-Duty Applications

The central drive dual-motor powertrain adopts a coordinated dual-motor architecture tailored for heavy-load and high-resistance scenarios. By synchronizing motor output based on operating conditions, the system ensures stable power delivery across varied terrain and load profiles, improving drivability in extreme working environments.

Key target application scenarios include:

- Long-haul trunk logistics

- Mining and off-road transport

- Port handling operations

- Urban construction vehicles

High-Efficiency Design and Performance Output

From a technical standpoint, the CD400-4E320 integrates a high-speed oil-cooled hairpin motor, a high-torque transmission system, and an integrated motor and transmission control unit. This compact configuration delivers more than 150 kilograms of weight reduction compared to equivalent single-motor solutions with similar output levels.

Performance highlights include:

- Maximum output torque of up to 27,000 Nm

- Peak system power reaching 600 kW

- Optimized power density for heavy commercial platforms

Intelligent Control and Energy Optimization

An advanced intelligent control strategy enables real-time allocation of workload between the two motors. This dynamic distribution enhances overall energy efficiency while maintaining consistent torque output under varying operational demands. The control architecture also contributes to smoother power transitions and improved system responsiveness.

Reliability-Oriented Engineering for Long-Term Operation

To ensure operational robustness, the central drive dual-motor powertrain features a redundant drive configuration designed to maintain functionality under fault conditions. The fully helical gear transmission minimizes noise and vibration, while bidirectional oil pump lubrication and multi-stage filtration improve thermal management and component longevity.

During development, core subsystems such as heat dissipation, lubrication pathways, and control logic were systematically optimized to support sustained performance in high-load, long-duration use cases. Technical collaboration and cooperation agreements have already been established with multiple vehicle manufacturers to support future application deployment.

Press Release

Click above to visit the official source.

Share: