Quick Takeaways

- ZF is introducing a software-led active noise reduction solution that cuts in-cabin tire noise without adding hardware, aligning with lightweighting and EV comfort needs.

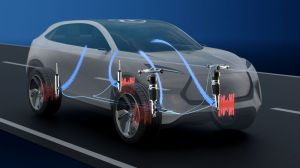

- The technology leverages chassis-level sensing and semi-active dampers to generate real-time counter-signals, with scalable applications beyond tire noise.

Active noise reduction software from ZF Friedrichshafen AG was confirmed for its global debut at CES 2026, marking a significant advancement in chassis-based noise control. The software-led solution is designed to reduce in-cabin tire noise without adding mechanical damping components, with series production planned from 2028.

Developed as part of ZF’s Chassis 2.0 strategy, the active noise reduction software relies on intelligent sensing and control rather than additional hardware. This approach supports vehicle lightweighting goals while improving acoustic comfort, a growing priority for electric and premium passenger vehicles.

Active Noise Reduction Software Enables Hardware-Free Noise Control

The system uses ZF’s Smart Chassis Sensor, which integrates an acceleration sensor to capture vibrations traveling through the vehicle structure. These vibrations are continuously monitored at the chassis level, allowing the software to identify noise behavior directly at the source rather than relying on cabin microphones.

Collected data is processed by an algorithm trained to recognize characteristic tire cavity noise patterns. These patterns typically occur around 200 hertz, a frequency range that strongly influences perceived road noise inside the vehicle, especially at highway speeds.

Chassis Software Generates Counter-Signals via Semi-Active Dampers

Once the vibration signature is identified, the active noise reduction software calculates a counter-signal in real time. This signal is executed through ZF’s cubiX motion control software, which precisely commands the semi-active damper valves.

Instead of altering the damper’s primary ride-control function, the system introduces micro-adjustments within the damper movement. These controlled micro-movements reduce noise interference while maintaining the intended suspension performance, ensuring no compromise between comfort and handling.

Measured Noise Reduction and Future Scalability

The current implementation of the active noise reduction software achieves in-vehicle noise reductions exceeding 3 decibels under real-world conditions. ZF indicates that future software iterations could deliver reductions of up to 10 decibels, depending on vehicle architecture and calibration depth.

Beyond tire noise mitigation, ZF plans to extend the same software logic to additional chassis actuators, including:

This scalable software-first approach positions chassis systems as active contributors to vehicle acoustics rather than passive structural elements.

Developed as part of ZF’s Chassis 2.0 strategy, the active noise reduction software relies on intelligent sensing and control rather than additional hardware. This approach supports vehicle lightweighting goals while improving acoustic comfort, a growing priority for electric and premium passenger vehicles.

Active Noise Reduction Software Enables Hardware-Free Noise Control

The system uses ZF’s Smart Chassis Sensor, which integrates an acceleration sensor to capture vibrations traveling through the vehicle structure. These vibrations are continuously monitored at the chassis level, allowing the software to identify noise behavior directly at the source rather than relying on cabin microphones.

Collected data is processed by an algorithm trained to recognize characteristic tire cavity noise patterns. These patterns typically occur around 200 hertz, a frequency range that strongly influences perceived road noise inside the vehicle, especially at highway speeds.

Chassis Software Generates Counter-Signals via Semi-Active Dampers

Once the vibration signature is identified, the active noise reduction software calculates a counter-signal in real time. This signal is executed through ZF’s cubiX motion control software, which precisely commands the semi-active damper valves.

Instead of altering the damper’s primary ride-control function, the system introduces micro-adjustments within the damper movement. These controlled micro-movements reduce noise interference while maintaining the intended suspension performance, ensuring no compromise between comfort and handling.

Measured Noise Reduction and Future Scalability

The current implementation of the active noise reduction software achieves in-vehicle noise reductions exceeding 3 decibels under real-world conditions. ZF indicates that future software iterations could deliver reductions of up to 10 decibels, depending on vehicle architecture and calibration depth.

Beyond tire noise mitigation, ZF plans to extend the same software logic to additional chassis actuators, including:

- Active brake squeal reduction

- Fully active damping systems such as sMOTION

- Expanded chassis-based acoustic control functions

This scalable software-first approach positions chassis systems as active contributors to vehicle acoustics rather than passive structural elements.

Company Press Release

Click above to visit the official source.

Share: