Quick Takeaways

- Advanced resin-based technology achieves mass production readiness for electrified vehicles

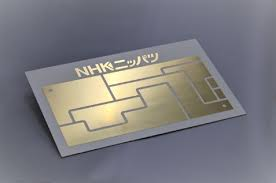

On January 15, NHK Spring EV power module substrate technology was announced as a newly developed metal substrate designed for high-performance electric vehicle applications. The solution has been selected by Denso Corporation for use in power modules within EV inverters, marking a major step forward in electrified drivetrain components.

NHK Spring EV power module substrate reaches mass production stage

This development represents the world’s first mass-produced resin-insulated substrate specifically engineered for electrified vehicles. The NHK Spring EV power module substrate combines a high heat-dissipation insulating resin sheet supplied by Sumitomo Bakelite Co. Ltd. with NHK Spring’s proprietary lamination and thick-copper circuit formation technologies.

Thermal performance comparable to ceramic substrates

Improved durability under temperature variation

NHK Spring EV power module substrate reaches mass production stage

This development represents the world’s first mass-produced resin-insulated substrate specifically engineered for electrified vehicles. The NHK Spring EV power module substrate combines a high heat-dissipation insulating resin sheet supplied by Sumitomo Bakelite Co. Ltd. with NHK Spring’s proprietary lamination and thick-copper circuit formation technologies.

Thermal performance comparable to ceramic substrates

- Despite replacing traditional ceramic insulation, the NHK Spring EV power module substrate delivers heat dissipation performance on par with ceramic-insulated alternatives.

- At the same time, it improves electrical efficiency by reducing power losses and suppressing electrical noise, which are critical factors in EV inverter reliability.

Improved durability under temperature variation

- By minimizing warpage caused by thermal cycling, the NHK Spring EV power module substrate enhances long-term durability and structural stability, supporting consistent inverter performance across varying operating conditions.

Company Press Release

Click above to visit the official source.

Share: